Katrangan Product

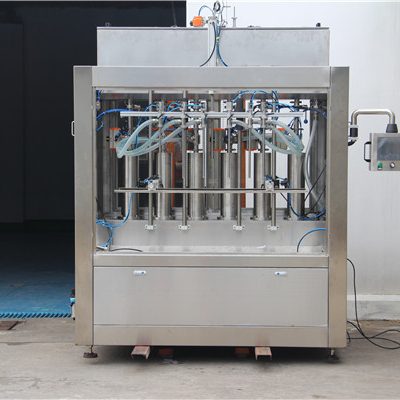

1. Garisan pangisi iki nggawe banyu ngombe laras 3 & 5 gelen.

2. Seri produksi produksi laras iki nggabungake mesin cuci, pangisi lan segel dadi siji unit.

3. Kanggo nggayuh tujuan ngumbah lan isterisasi, mesin cuci nganggo pirang-pirang suntikan cairan lan disemprotake, lan solusi cuci bisa digunakake kanthi bunder. Segel bisa nutup segel tutup kanthi otomatis.

4. Garis pangisi iki nglengkapi piranti nyemprot banyu kanggo nutupi tutup botol supaya mesthekake tutup kasebut aseptik lan sehat.

5. Garis iki uga bisa kanthi otomatis nindakake ngumbah botol, sterilisasi, ngisi, capping, ngetang lan ngilangi produk.

6. Wis fitur lengkap, desain novel, lan tingkat otomatisasi kanthi dhuwur. Iki minangka jinis prodhuksi otomatis laras banyu laras, sing nggabungake mekanisme, teknologi listrik lan pneumatik.

Parameter Teknik Utama

| Model | QGF-100 | QGF-200 | QGF-300 | QGF-450 | QGF-600 | QGF-900 | QGF-1200 |

| Kepala ngiseni | 1 | 2 | 3 | 4 | 4 | 6 | 8 |

| Jilid | 18.9cbm | 18.9cbm | 18.9cbm | 18.9cbm | 18.9cbm | 18.9cbm | 18.9cbm |

| Ukuran barel | Φ270 * 490mm | Φ270 * 490mm | Φ270 * 490mm | Φ270 * 490mm | Φ270 * 490mm | Φ270 * 490mm | Φ270 * 490mm |

| Kapasitas | 100 | 200 | 300 | 450 | 600 | 900 | 1200 |

| Tekanan gas | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.6 | 0.6 | 0.6 |

| Konsumsi gas | 0.37 | 0.37 | 0.6 | 0.8 | 1 | 1.5 | 1.8 |

| Daya motor | 1.38W | 1.75W | 3.8W | 3.8W | 7.5W | 9.75W | 13.5W |

| Tegangan voltase | 380V / 50Hz | 380V / 50Hz | 380V / 50Hz | 380V / 50Hz | 380V / 50Hz | 380V / 50Hz | 380V / 50Hz |

| Bobot | 680kg | 800kg | 1500kg | 2100kg | 3000kg | 3500kg | 4500kg |

Komponen listrik kanggo mesin utama

| Ora | Jeneng | Merek | Asal saka panggonan |

| 1 | Ngalih otomatis | Zhengtai | Zhejiang |

| 2 | PLC | Mitsubishi | Jepang |

| 3 | Tombol, tombol, tombol lampu | Schneider | Prancis |

| 4 | Silinder udara | Sanli | Hangzhou |

| 5 | Pompa banyu kanggo diisi | Nanfang | Hangzhou |

| 6 | Pompa banyu kanggo diisi | Nanfang | Hangzhou |

| 7 | Silinder udara saka batang utama | AIRTAC | Taiwan |

| 8 | Angkat silinder udara | AIRTAC | Taiwan |

| 9 | Siluk udara sing dipasang | AIRTAC | Taiwan |

| 10 | Silinder udara kanggo nyurung tong kosong | AIRTAC | Taiwan |

| 11 | Silinder udara kanggo katup isi | AIRTAC | Taiwan |

| 12 | Penangan sumber udara | AIRTAC | Taiwan |

| 13 | Pipa udara, sendi, lsp | AIRTAC | Taiwan |

| 14 | Semprotan nozzle | Shanghai | Shanghai |

| 15 | Plato chain | SUS 304 | Perusahaan kita |

| 16 | Katup mlebu banyu | SUS 304 | Perusahaan kita |

| 17 | Klep ngisi | SUS 304 | Perusahaan kita |

Rincian cepet

Jinis: Mesin Isi

Kondisi: Anyar

Aplikasi: Sandhangan, Minuman, Kimia, Komoditas, Pangan, Mesin & Hardware, Kesehatan, Tekstil

Jinis Kemasan: Kantong, Laras, Botol, Kantong, Kapsul, Karton, Kasus, Kantong, Kantong Nganti

Bahan Kemasan: Kaca, Logam, Kertas, Plastik, Kayu

Gred otomatis: Otomatis

Jenis Dipandu: Listrik

Tegangan: 220V / 380V

Daya: 3.5kw

Panggonan Asal: Shanghai, China (Mainland)

Jeneng merek: VKPAK

Nomer Model: Mesin ngisi galon 5

Ukuran (L * W * H): 2350 * 1610 * 2250 mm

Bobot: 2500kg

Sertifikasi: CE ISO SGS

Layanan sawise adol sing diwenehake: Engineers kasedhiya kanggo mesin layanan ing luar negeri

Kapasitas: 1.00-1200 botol saben jam

bagean cadhangan: Klebu FREE

mesin sing ndhukung: kabeh klebu

Instalasi: insinyur profesional

Kontrol PLC: Mitsubishi, Omron, Siemens lsp

Layar tutul: Mitsubishi, Siemens, Proface

Ngalih Udara: Schneider

Breaker Circuit: Schneider

Hubungi: Schneider

Ngalih Foto Foto: OMRON, KEYENCE, P + F

* QGF Series automatic production line is specialized for the production of 3-5 gallon barrel.

* The machine consists of washing, filling and sealing in one

* The bottle washer adopts multi-channel washing liquid injection and disinfectant injection for the purpose of washing sterilization.The disinfectant is recyclable.

* The sealing machine can start sealing automatically and the bottle conveying port is equipped with a sanitation device to ensure the sanitation of cap.

* Washing, disinfection, filling ,gland, counting and discharging is automatic.

* The major electrical apparatus are all products of well-known brands, such as SIMENS, MITSUBISHI ,Schneider and OMRON.

* The production line is an ideal choice for mineral water,distilled water and purified water with impact structure ,small occupation of land and high automation.